40+ Annual

Experience

Founded in 1978 in İzmir, EKİPSAN has been committed to meeting customer demands and expectations with a focus on high quality and cost efficiency from day one.

Driven by the responsibility that comes with our customers’ trust, we enhanced our production capabilities in 2000 by adding a pressing capacity ranging from 30 to 1500 tons. This expansion was accompanied by our relocation to a new facility in İzmir-Kemalpaşa, built on a 14,000 m² area (9,400 m² covered), increasing our production capacity to 10,000 tons per year. With a deep-rooted background in metal processing, EKİPSAN can provide sustainable solutions to the automotive industry.

In the last quarter of 2024, with our renewed management approach, we adopted the principle of delivering time and cost advantages without compromising on quality, by integrating technology and experience to meet both mass production and custom manufacturing needs of the industries we serve as a solution partner.

With our extensive machinery, skilled labor team, and certified quality systems, we continue to be a trusted partner by providing a fully traceable end-to-end production process tailored to our customers’ needs.

A Reliable Solution Partner in the Automotive Industry

As a trusted solution partner to Turkey’s leading automotive and industrial companies (including BMC, Ege Fren, Ege Endüstri, Krone, Cummins, and others), Ekipsan stands out in the sector by combining customer satisfaction, engineering excellence, and on-time delivery.

With a sector-specific approach, years of experience, and a flexible production mindset, Ekipsan is a reliable manufacturing partner that meets the high-quality expectations of the automotive industry.

In addition to high-volume serial production, Ekipsan also offers competitive solutions for low-volume, custom parts. Thanks to its MRP II-based production planning infrastructure, all processes can be monitored and managed efficiently. Ekipsan manufactures in compliance with international standards, certified by IATF 16949 and ISO 9001.

Our planning and facility infrastructure has the flexibility to successfully meet both mass and special production demands.

We provide fast and effective feedback in process design, quotation and sample production processes.

We provide advantage to our customers with our competitive pricing policy in low and high volume orders.

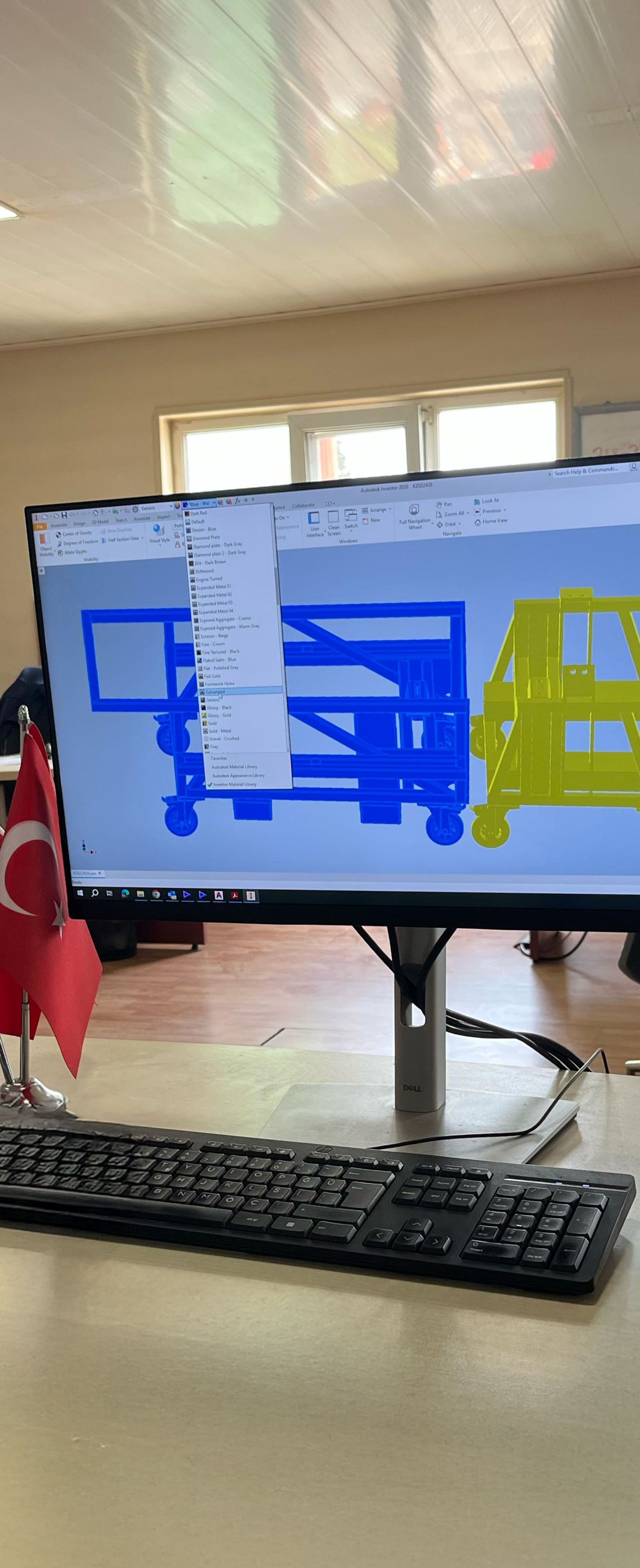

We accelerate your projects by performing process design, mold and apparatus production in our own facility.

All Our Services See All

Process Design & Engineering Services

By carefully evaluating our customers' requests and needs, we develop economical and efficient methods to suit each customer's needs.

Examine

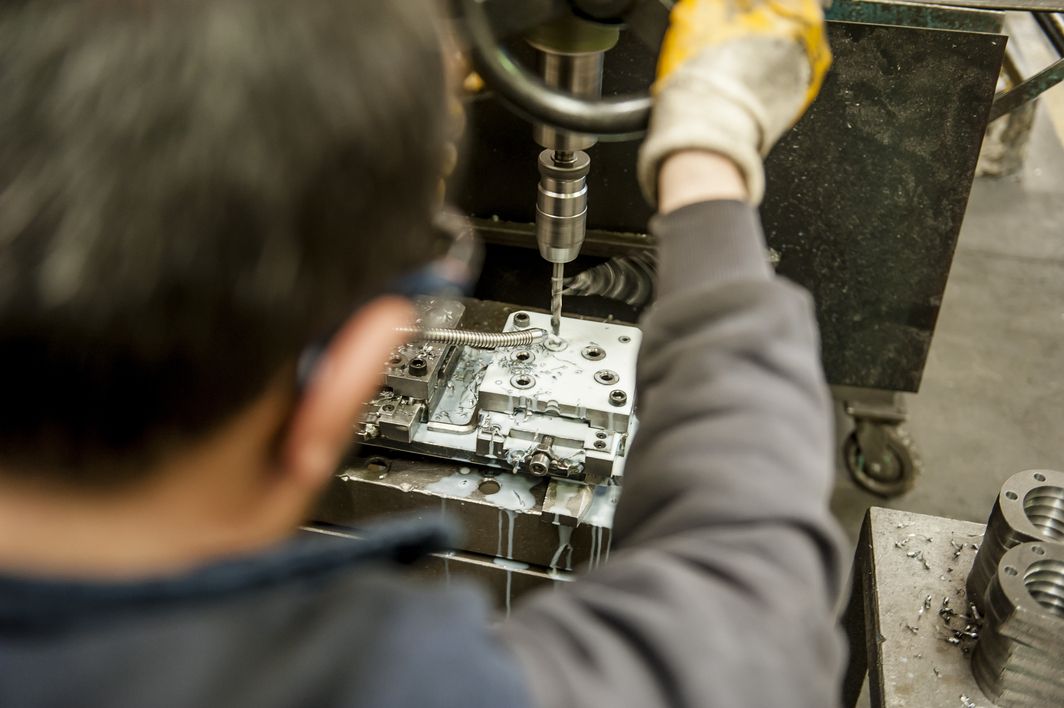

Die Design

We design and produce special apparatus and mold systems for material shaping, cutting and drilling operations.

Examine

Electrostatic Powder & Liquid Coating

In our company, powder coating and wet paint applications are carried out by our expert team.

Examine

Machining

We manufacture mold modifications and manufacturing, as well as all machining in accordance with technical and dimensional specifications.

Examine

Welded Manufacturing & Assembly

All weldable steel and aluminum groups are among the materials we use in our production processes.

Examine

Press Brake

We meet your bending demands with our 6-axis press brake machines with a length of 1500-4000 mm and our large mold stock.

Examine

Pressing

We serve customer demands with a total of 18 presses, including eccentric and hydraulic types, ranging from 30 to 1500 tons in our press line.

Examine

Laser & Plasma Cutting

We cut aluminum, stainless and black sheet metal with a thickness of 0.5-40 mm with our laser cutting machines.

Examine

Blog & Sectoral Shares

Discover our blog content to follow innovations in the automotive and manufacturing sectors, news from Ekipsan and expert opinions.

The Importance of Integrated Production in the Automotive Industry

In today’s rapidly evolving and highly competitive automotive industry, managing all production processes — from design to assembly — under one roof has become increasingly important.

Read more